Residential Construction

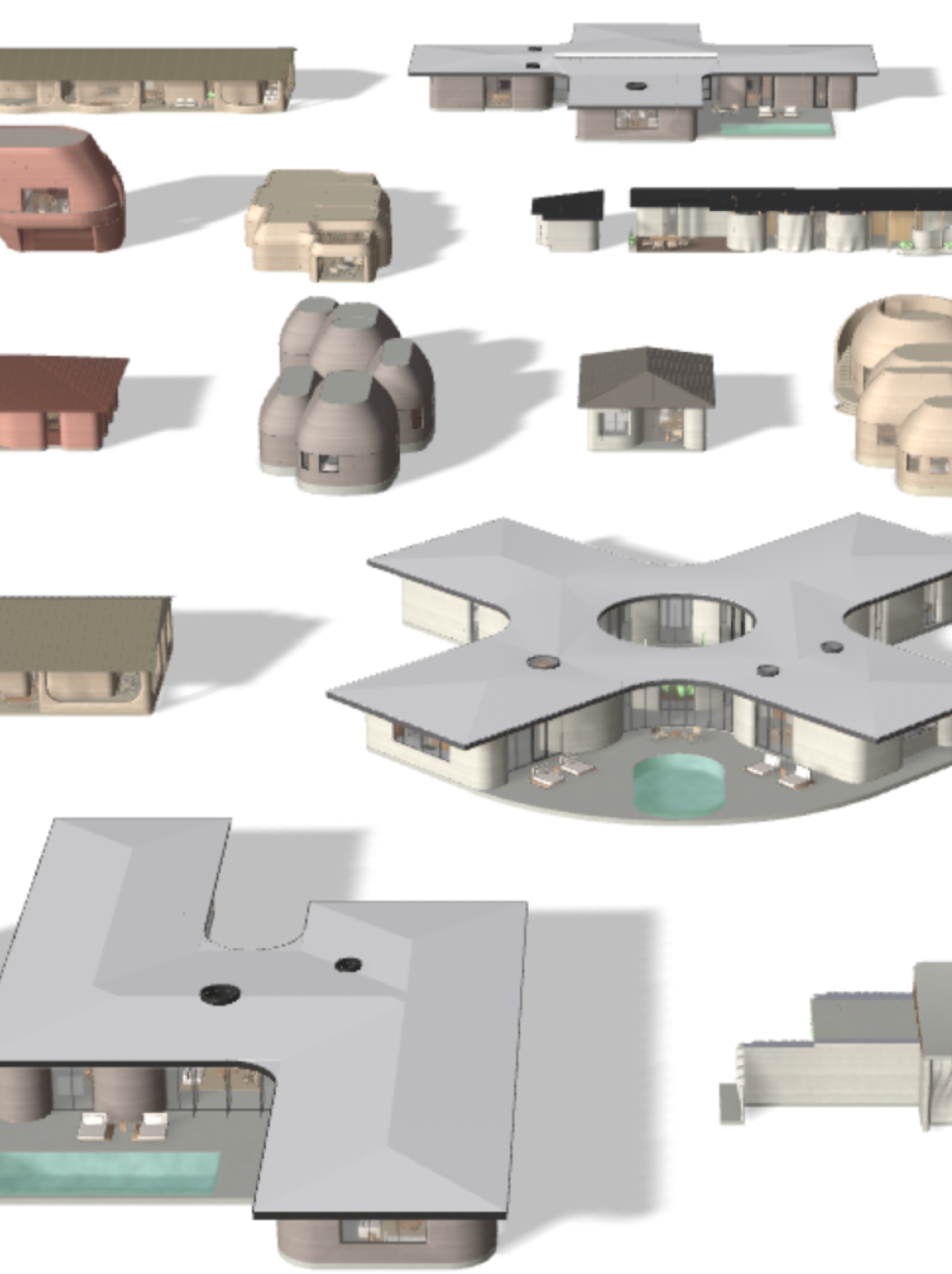

ICON Available Homes

Explore ICON homes available today. From the Sunday Homes at El Cosmico in euphoric Marfa, TX to the Genesis Collection at Wolf Ranch in picturesque Georgetown, TX we have homes to meet every aesthetic. New projects will be revealed soon.

Off-World

From the Moon to Mars

To help accelerate humanity’s expansion into the stars, ICON now offers robotic arms, actuators, simulants, and testing facilities to fellow private space startups and companies. Explore our offerings and get in touch with the team today.

i99 Winners Revealed

Announced during ICON's official SXSW showcase event, winners of the global architecture competition received their prizes and their designs are now a featured collection in ICON's CODEX.